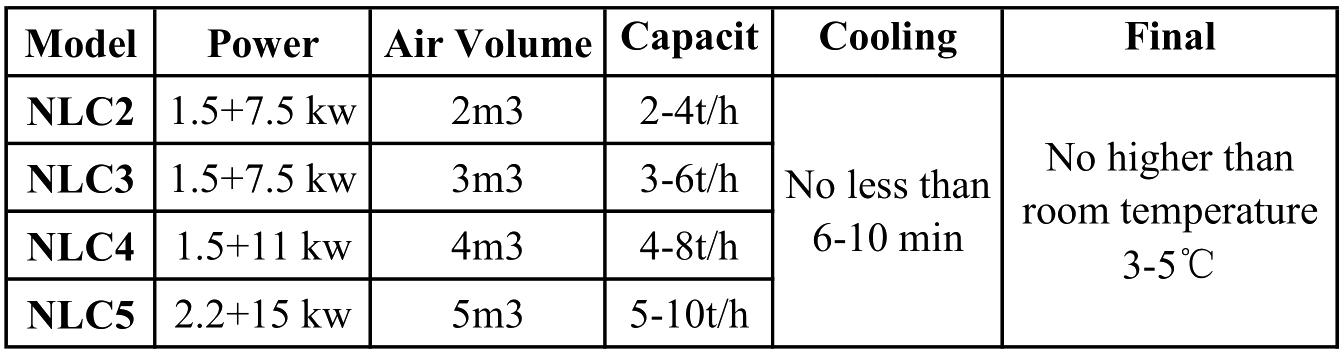

Pellet Cooler Machine NLC2

2m3 Biomass Cooler

Pellet cooler – cooling machine + screening machine.

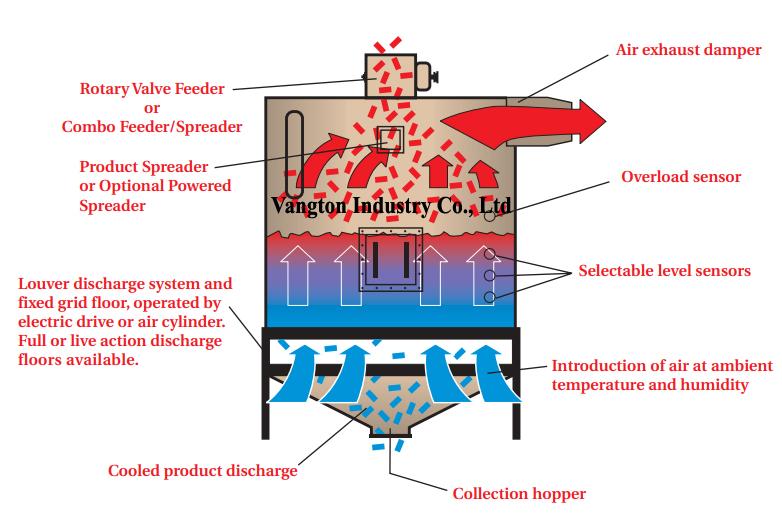

Biomass cooler usually use for lower the temperature of finished pellets. The speed is very fast.When the hot biomass pellets fall down in to the cooler body, to avoid adhesion, the warmed air and power will be pull out at the same time.

To get a high efficiency, cold air blows from the opposite direction, and the fine particles are easy to be blow out.

Cooling principle:

The high temperature and high humidity pellets are cooled with the help of counter current cooling principle. Hot air contacts hot pellets, cold air contacts could pellets, so that the surface cracks (it may caused by sudden cooling) can be avoid. The air-lock can inlet more air, to get a high efficient.

The discharged pellets from pellet mill is about 60-80 ℃, the water content is about 15%. The pellet cooler not only makes pellets cooler, but at the same time can reduce 3-4% water content. Wood pellets with 12% moisture are easy to stove.

Features of Biomass Cooler

1. The cooled pellets’ temperature will be no more than 3-5 degrees higher than the room temperature

2. The discharge systerm is stable and reliable

3. Can be used for different kinds of pellets

4. Low energy consumption and easy operation