Pellet Cooling Machine NLC3

3m3 Biomass Cooler

Our pellet cooler is counter flow type. Pellets fall down and meet the cool air in the cooler’s main body. It also has a shaking screen, which can remove not qualified pellets.

Cooling and Screening Process

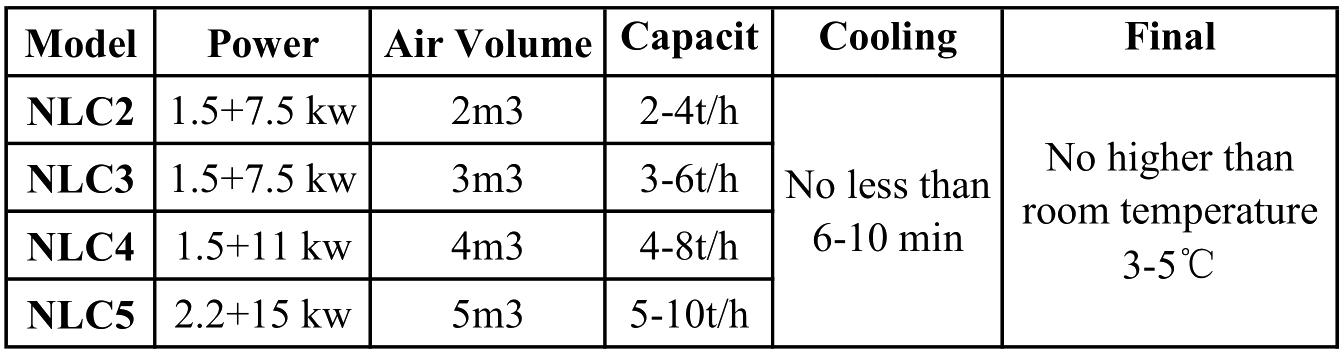

The cooling and screening process is the process that can reduce finished pellets’ temperature from about 80 ℃ to room temperature and to reduce the moisture from about 15% to 12%. To achieve a better storage, this process is in need. Using our biomass cooler, the finished pellets’ recherche will be less 3-5 ℃ higher than the room temperature.

Advantages of Pellet Cooler

1. Avoid surface crack, improve the rate of qualified products

2. Large capacity, high efficiency, high degree of automation, low noise, easy to use