High Consistency Pulper

High Consistency Hydrapulper

High consistency hydrapulper is used for high concentration crushing of waste paper. The rotor combines a three-wing and a toothed flying rod to create a strong interfiber friction, thus speeding up the fiber separation speed of the waste paper.

High consistency hydrapulper is designed with reference to foreign data and is mainly used for the deinking process of waste paper. The waste paper can be rapidly decomposed at a high concentration and a water temperature of 60-90 ° C, and the ink particles are separated from the fibers by the action of a chemical agent, and the ink particles and impurities remain in the original size. Perform the following ink removal, screening and purification processes as much as possible. Finally, the use of waste paper can produce high whiteness pulp, which saves steam, medicine and electricity. High consistency hydrating agents have become one of the essential core equipments in the deinking and pulping process of waste paper.

Application & Feature

- It is mainly used for the separation of waste paper and ink at high concentration in the process of deinking of waste paper.

- The special spiral rotor effectively promotes the circulation and turnover of the pulp, enhancing the friction between the fibers. Finally, a soft pulp is obtained at a high consistency, and no impurities are broken during the fiber embossing and deinking process.

- Treatment of 12%-18% high consistency pulp, effective chemical mixture and friction between the fibers at high consistency allows the ink particles to be completely separated from the fiber surface.

- Compact structure and easy operation and maintenance.

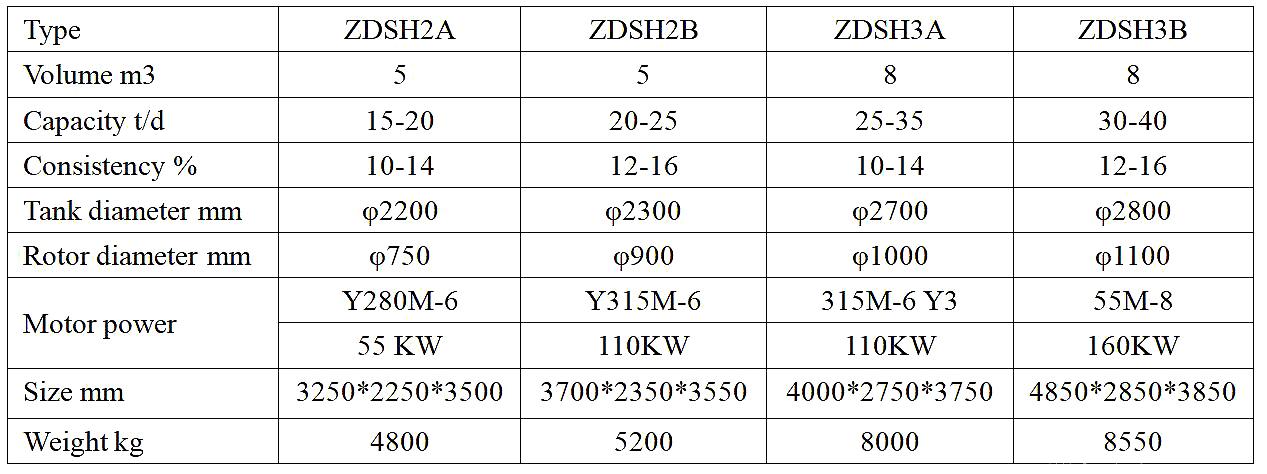

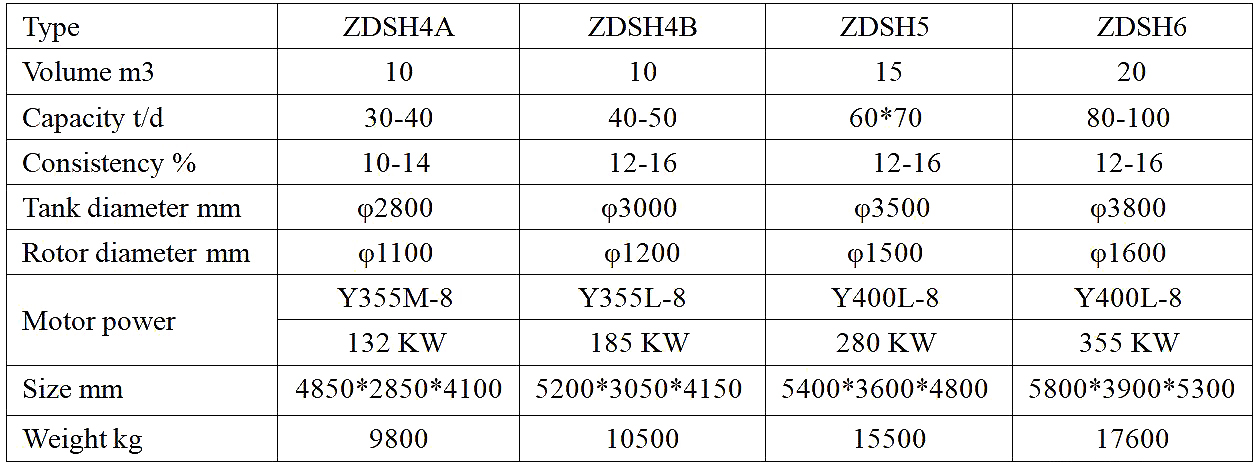

Main Specification

The capacity will vary depending on feed size, feed rate, operating conditions, desired product yield, feed characteristics and equipment configuration.