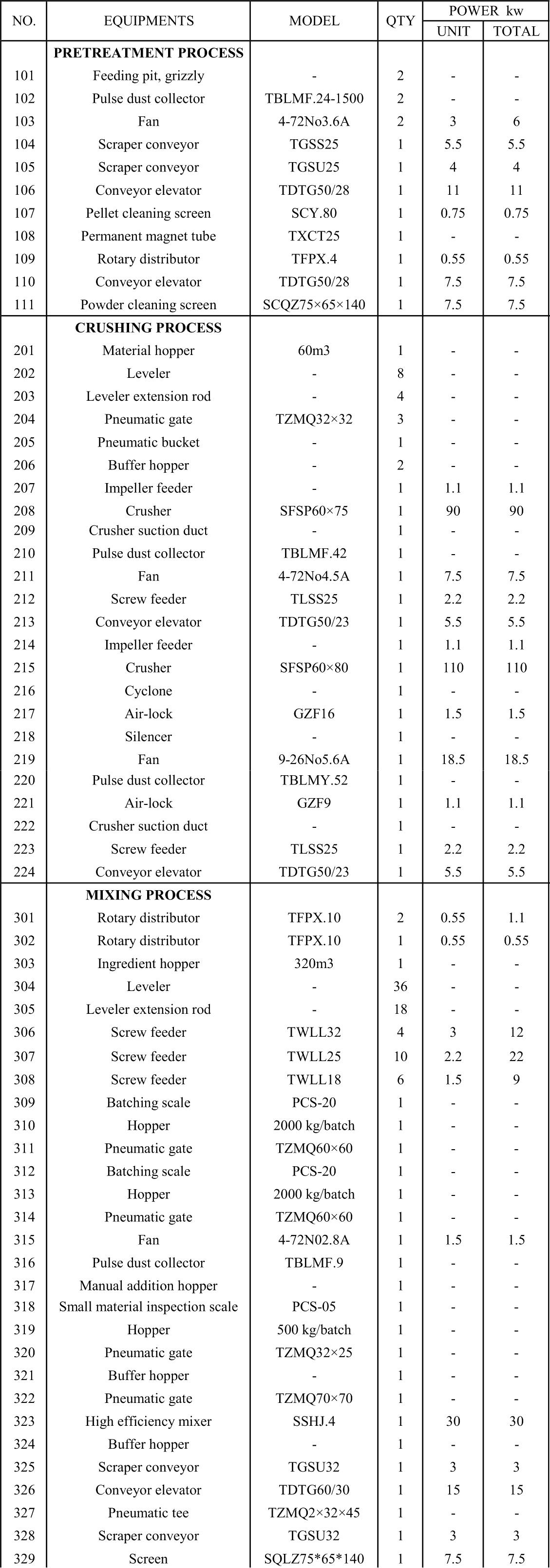

Feed Pellet Machine Line 10t 20t

Industry feed pellet making line

This feed pellet machine plant can use raw materials below: Corn, brown rice, rice, sorghum, soybean and others.

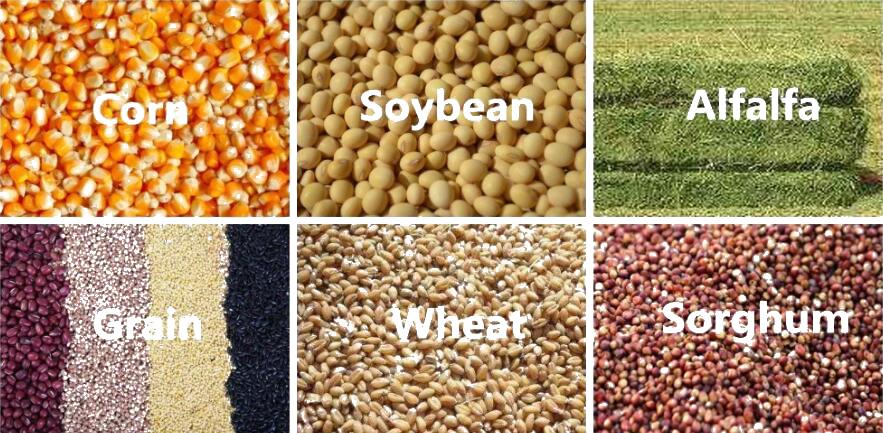

The process of animal feed processing line is as follows: Grinding process – mixing process – granulation process – cooling process – packaging process

Material cleaning, screening and receiving process

After receiving the material, our factory will use granular cleaners and flour cleaners to clean dust and other debris, and then use a magnetic cylinder to clean the iron and metal in the material. After cleaning, the material will be sent to the next process.

Raw material grinding process

General purpose product with stable performance. It is widely used for crushing raw materials in large and medium-sized feed and food processing enterprises.

Mixing process

Ingredients / batch design formula according to the nutritional needs of different animals, using specific equipment to accurately weigh various ingredients. Mixing refers to the operation of measuring and mixing various feed ingredients to form a uniform distribution under the action of external forces. This process uses two batching scales and multiple batching boxes, and the trace components are manually added by the checkweigher. After the batching of the materials is completed, they enter the mixer for mixing, and finally the materials are output through the conveyor and the elevator.

Feed pelleting process

The main drive uses high-precision gear drive, and the output is about 20% higher than that of belt drive.

Imported high-quality bearings and oil seals are used to ensure that the machine runs efficiently, stably and with low noise.

The feeder is made of stainless steel, and the quality of the discharged particles is ensured by using a variable frequency motor.

Feed pellet cooling process

The latest octagonal cooling box design has no cooling dead ends. It adopts closed feeder to feed and enter the air zone, and the cooling effect is significant. The unloading is evenly stacked in the cabin; the slide valve reciprocating unloading mechanism is adopted, and the movement is stable, reliable and less residue. Low energy consumption and easy operation. The temperature of the finished product after cooling is not higher than room temperature +3 oC ~ 5 oC, which is suitable for the cooling of granular materials.

Feed pellet crushing process

The diameter of the feed pellets can be customized through different die holes, but the length can also be adjusted by the feed pellet mill. Drum-type feed pellet mill is an ideal equipment for crushing feed pellets. Double-roll feed pellet mill is suitable for crushing chicken, duck, goose and other feed pellets.

Feed pellet screening and grading process

The combination of circular, elliptical, and straight movements has a good screening effect. Screened boat driver with shielded belt, emphasis on balance and low noise.

The rear support of the screen is an improved elastic support with low vibration and low noise. Strengthen the base to ensure more balanced operation of the equipment.

Packaging process of feed pellets

Suitable for materials with poor fluidity. In the weighing mechanism, the hopper on the system has an air suction port, which can effectively control the overflow of dust from the equipment, ensure that the dust is concentrated in the working environment, and keep the pressure of the scale body in balance with the outside world. , To avoid the impact of airflow weighing accuracy.

Packaging accuracy: 0.1% Packaging range: 5-50kg / bag