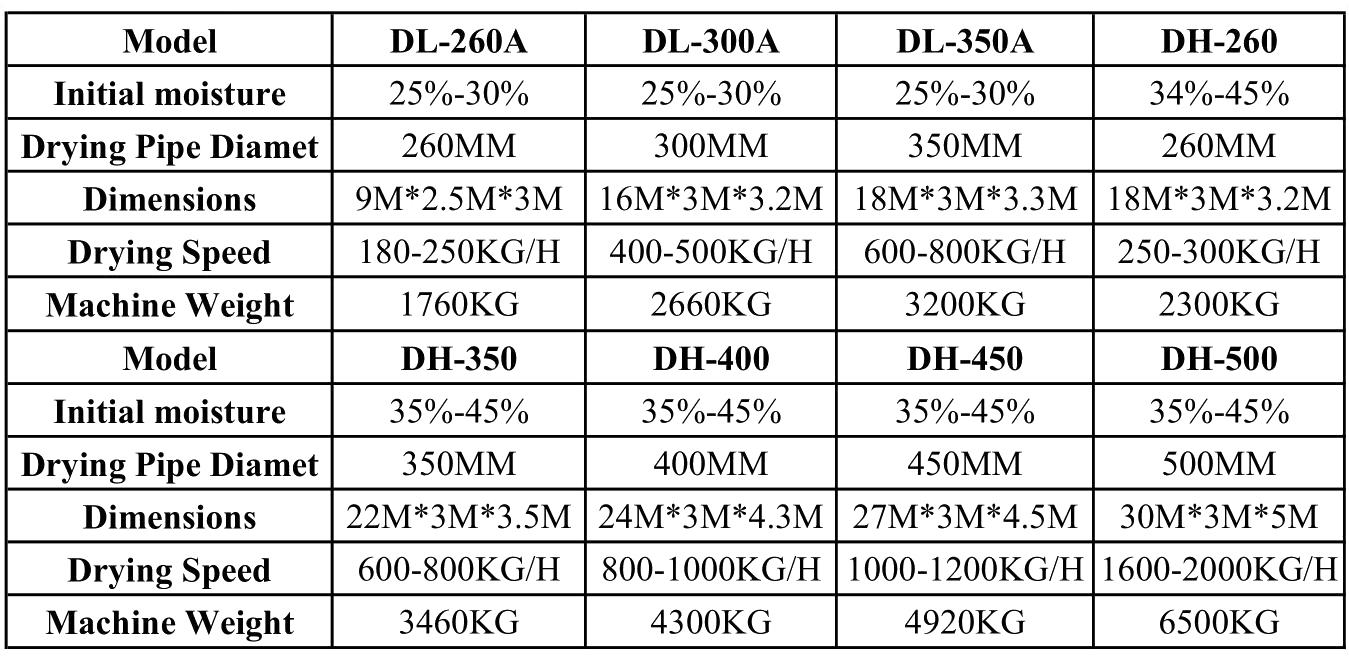

Air-flow Dryer DH450

35-45% moisture, 1-1.2t/h

The air flow dryer is using hot air from a hot blast stove to dry materials. This machine is suitable for different materials, such as wood chips, different kinds of grains and straws and other materials.

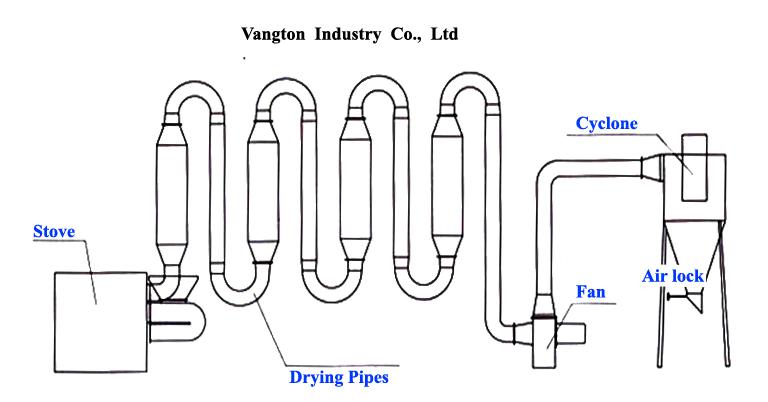

The dryers can be used together to achieve very high humidity, which results in greater production demand. The air dryer is composed of a hot air stove, a screw feeder, a buffer device, a blower, pipes and a cyclone separator. The working process is to form the air flow through the negative pressure of the blower. The material enters the pipeline through the screw feeder, so that the hot air and the material are mixed together. When passing through the cyclone separator, the moisture in the material is separated.

The air flow dryer is widely used.

Strong drying strength, saving equipment investment: The maximum capacity of pneumatic dryer. The evaporative moisture capacity of the equipment we manufacture will be 50-150kg / hr. Small equipment size, saving investment. The advantage is unmatched by other drying equipment. High automation content and good product quality: the raw materials to be dried are in the pipeline. Short drying time (only 0.5-2 seconds). This allows automation. Raw materials must not come into contact with foreign substances.