Biomass Pellet Machine LIne

capacity: 1-1.5t/h

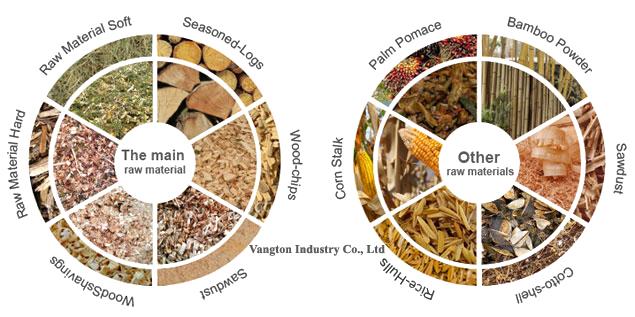

We provide customized line for pellet making. Our engineer team will design the line depend on client’s raw materials and request of the finished pellets.

Wood Pellet Production Line

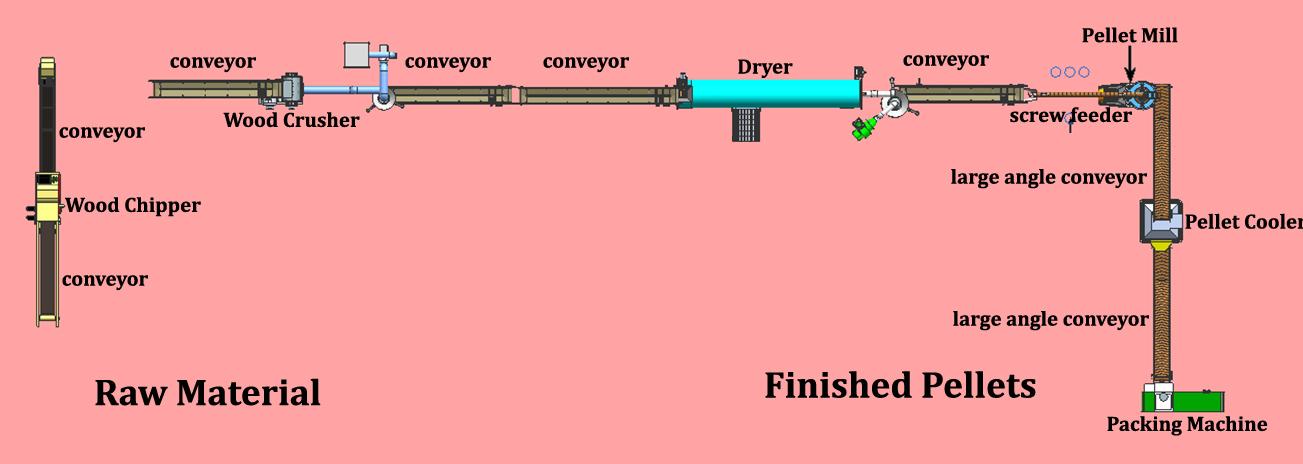

A completed biomass producing line usually has these processes: Chipping process, Crushing process, Drying process, Pelletizing process, Cooling Screening process and Packing process.

1. Chipping process – the main machine is Wood Chipper

This process is a pretreatment. Usually the raw material’s size are big, like wood wast, wood logs. So before crushing, firstly we need to make them smaller, for example 3-5 cm. So that the capacity of wood crusher will be high, and can save the total cost of the line. If clients need small capacity, or the raw material is not big. We don’t need this step, can use chipping crusher machine or directly start from wood crusher.

2. Crushing process – the main machine is Hammer Mill

Hammer mill crushes the chipped materials from the first process into 3-10mm sawdust (or powder). Different pellets have different request, our hammer mills have screens with different sizes of whole. Client can choose.

3. Drying process – the main machine is Drum Rotary Dryer

To make sure the moisture of sawdust is suitable for peelitizing, we have a dryer before pellet mill. Depends on different capacity, the dryer can be Air-flow dryer, Drum Rotary Dryer or Vacuum Drum Dryer. The suitable moisture is around 15%.

4. Pelletzing process – the main machine is Pellet Mill

The pellet mill, it also called as pellet press. Is the most important machine in the producing line. Pellet mill is the center, other machines are work for him. The pellet mill presses crushed and dried material into pellets. From 0.6-0.8 t/h, we suggest to use Ring Die Pellet Mill. It is very classic and has good performance.

5. Cooling process – the main machine is Pellet Cooler

Cooling process is also important. After pellitizing, the pellets’ temperature is high. Cooling machine will reduce it’s temperature and moisture, at the same time unqualified pellets will be removed. The final temperature will be room temperature and the final moisture is about 12%.

6. Packing process – the main machine is Pellet Packing Machine

Packing machines packs pellets into bags (15 kg, 25 kg, 50 kg, 1000 kg). When go to the market. Pellets will looks beautiful and sell good.

Here, we wish all the clients sell well.

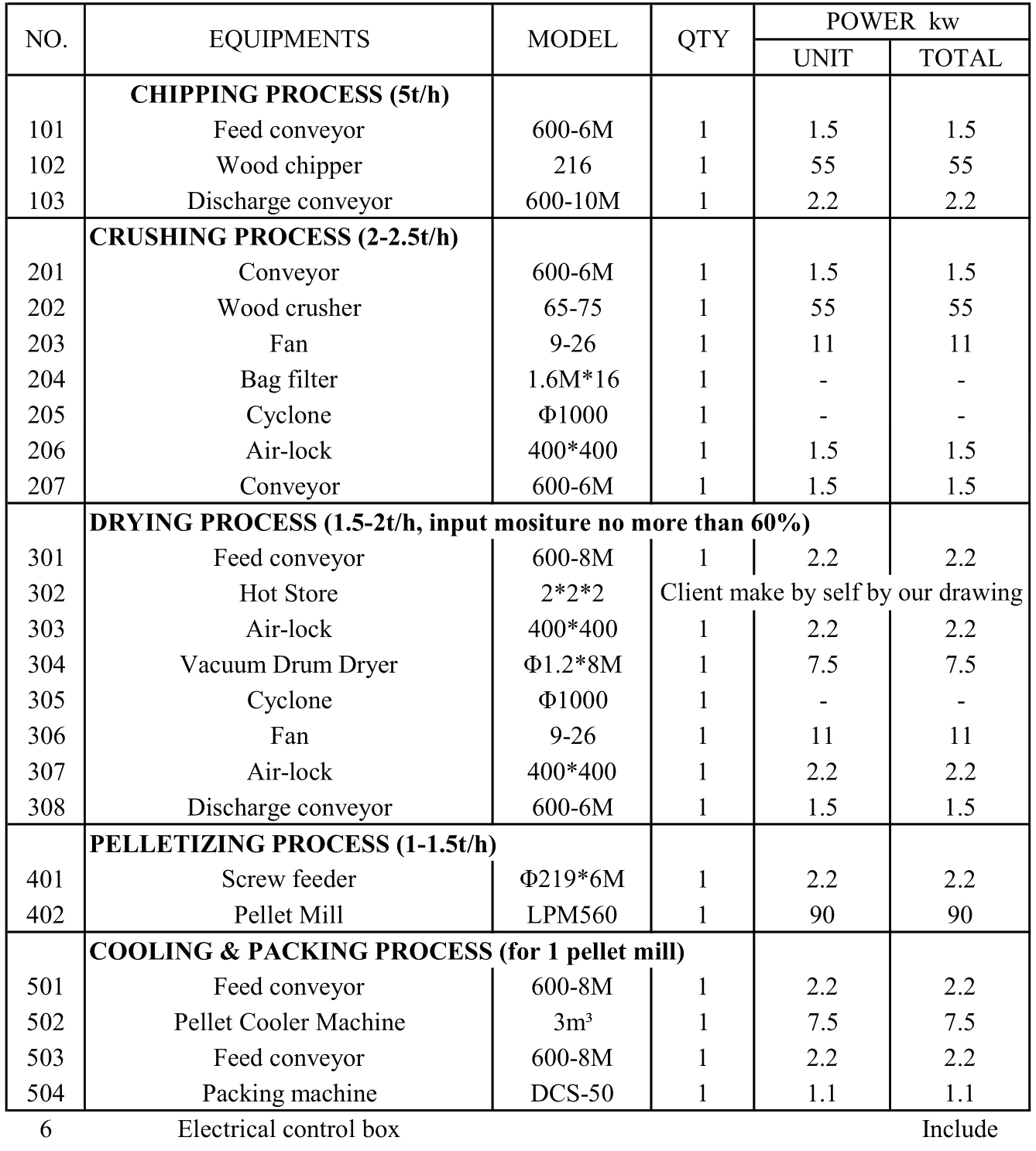

Equipments for 1-1.5t/h Producing Line

(The below equipmets are for example. The detailed plant should according to the client’s needs)

Related equipments

- Chipping Process —— Drum wood chipper GWC216

- Crushing Process —— Wood crusher LHM65x75

- Drying Process —— Vacuum drum dryer VD1.2*8

- Pelletizing Process —— Pellet machine LPM560

- Cooling Process —— Pellet cooler NLC3, Packing machine DCS-50