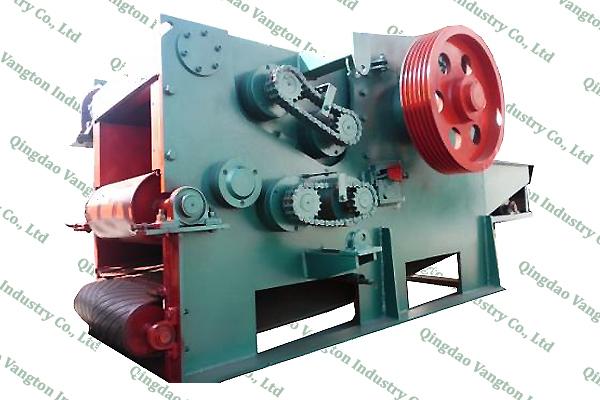

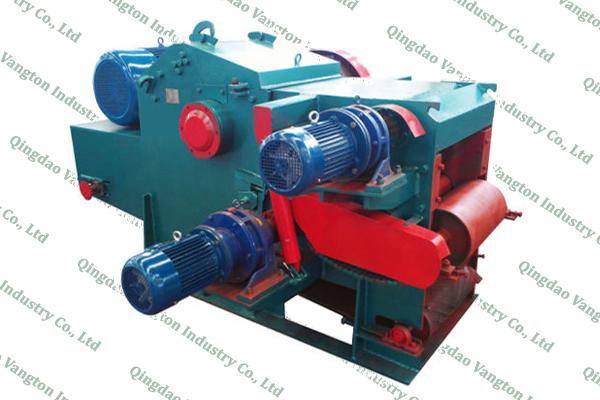

Disc Wood Chipper

Disc wood chipper have very small and very big model, can process logs with different diameters.

The disc wood chipper is mainly process round wood, branches, bamboo, cotton stalks into smaller and uniform chips, used in the pulp and paper industry, the biomass industry, fiber and particle board factories, and is also very suitable for modern high-intensity burning fuel in heating systems.

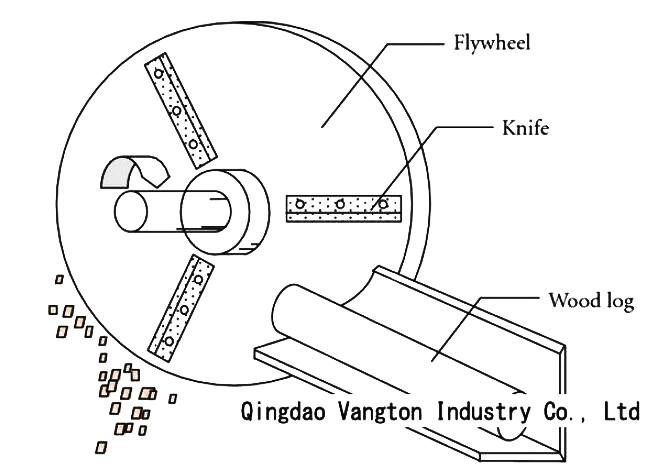

The basic principle is as follows:

The disc is placed vertically, a cutting tool is placed on the circumference of one side of the surface of the disc and a spindle is placed in the center of the disc to rotate the disc at high speed. Another conveyor parallel to the main axis can transfer material to the circular periphery of the disc. The material is cut with a knife at the periphery of the disc.

The conveyor’s speed and disc rotating speed are adjustable, so the thickness of the final product can be adjusted.

Advantages of wood chipper

1. Use a wood chipper to cut wood and branches into pieces.

For artificial wood board materials.

2. The chipper can be equipped with electric motor or diesel engine. This uses a flaker

Designed to make delicate wood chips. Chips can be used in pulp and paper mills,

Particleboard factory, etc.

3. The blade size of the chipper is 10 ~ 30mm.