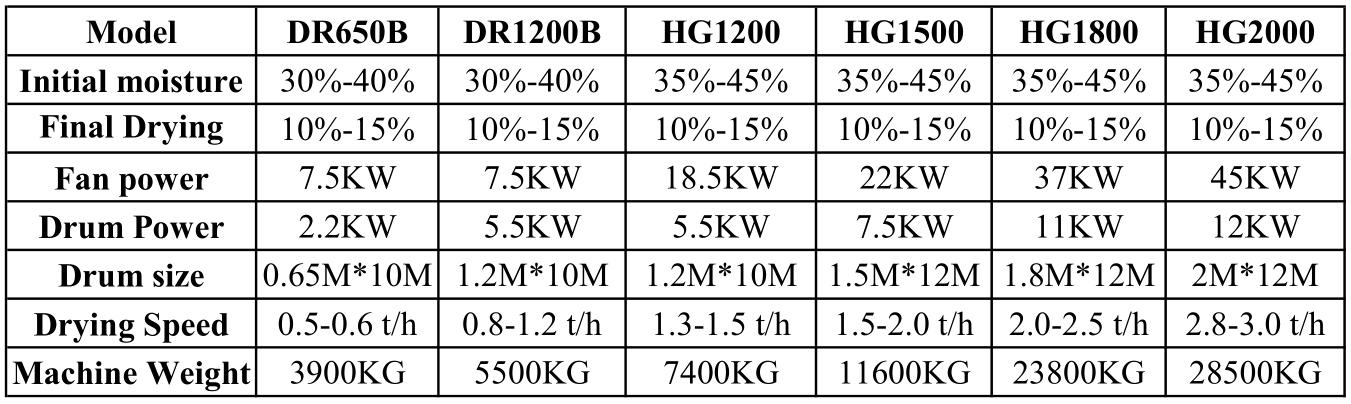

Drum Rotary Dryer DR650B

30-40% moisture, 0.5-0.6t/h

Drum rotary dryers are used for drying water from raw materials using a drying drum. In the drum during the drying process, raw materials are dried by a rotating drum, thereby producing a drum-dried product. Drum dryers are suitable for industries such as fuel plants, fertilizer plants, chemical plants, and pharmaceuticals.

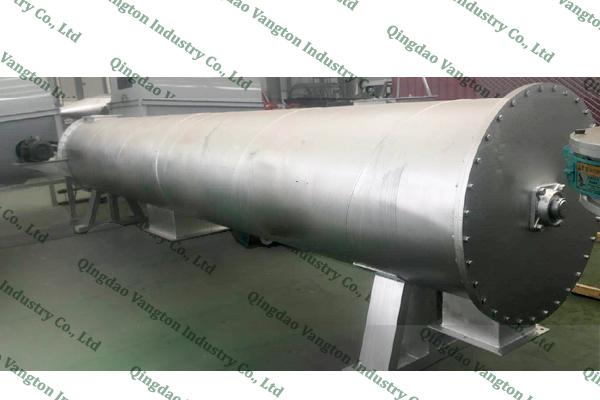

Drum Rotary Dryer Introduction:

It is suitable for dry and sensitive materials such as sawdust, rice husks, ground wheat straw, ground cotton / corn straw, etc.

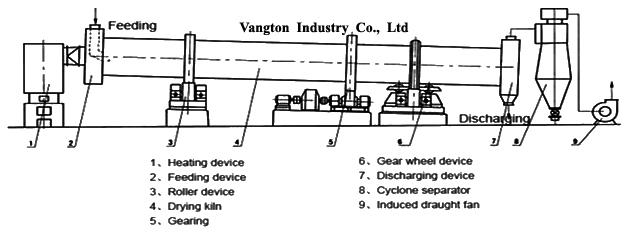

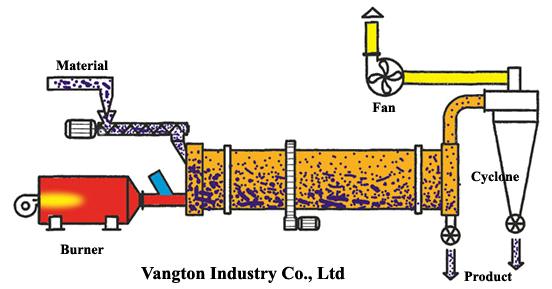

It consists of hot air stove, main drum, pipes, cyclones, fan, air lock.

It can reduce moisture to 15% or even less.

Furnace fuel: wood waste, coal. Waste oil, etc.

(Note: If the moisture content of the raw material is greater than 45%, the stove needs to be larger, please inform us when ordering.)

Description of drum rotary dryer:

The rotary dryer consists of a furnace and a main rotating body, which can reduce the moisture from 60% to 10%. Our drum dryers have a water evaporation capacity of 250 kg to 8000 kg per hour. The final product is different for materials with different densities; the final output may also be different for raw materials with different moisture contents.

Advantages of drum rotary dryer:

1). The air heating system can efficiently remove water of the material.

2). No pollution to the target materials, which can ensure the loss of color, flavor and nutrition to a minimum;

3). The smoke collector used in conjunction with the air heating system adopts a water cycle wet collection method, which can ensure that the exhaust gas meets environmental protection requirements and consumes minimal water.