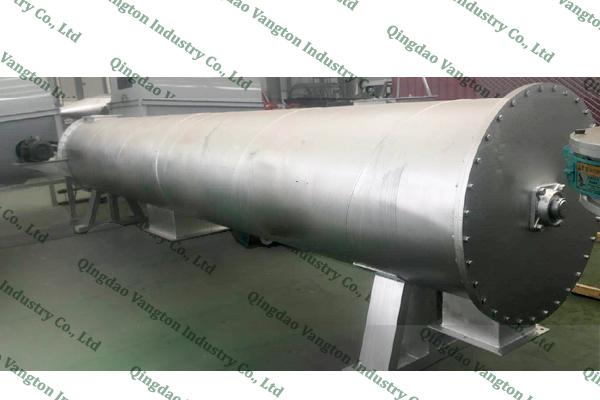

Drum Rotary Dryer HG1000

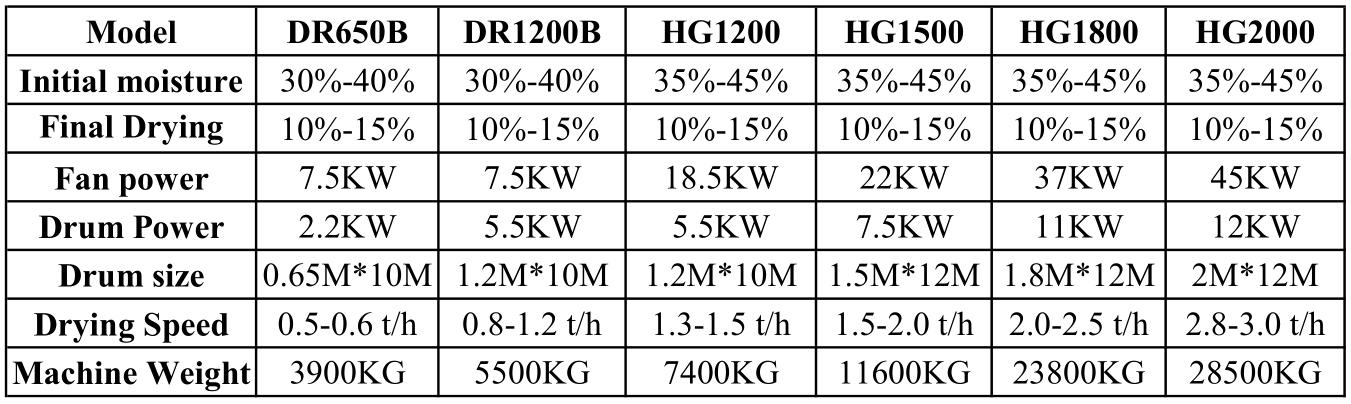

35-45% moisture, 0.7-0.9t/h

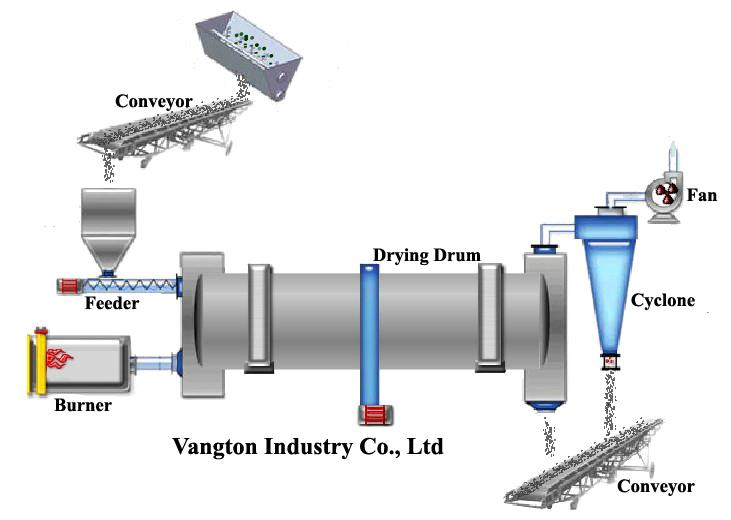

Drum rotary dryers are used for drying water from raw materials using a drying drum. In the drum during the drying process, raw materials are dried by a rotating drum, thereby producing a drum-dried product. Drum dryers are suitable for industries such as fuel plants, fertilizer plants, chemical plants, and pharmaceuticals.

Features of drum rotary dryer

Sturdy construction

Allows higher drying temperatures

Relatively long residence time

When the material is transported along the length, the drum will disperse

Benefits of drum rotary dryer

– Combining flexibility with reliability extends service life. Rotating devices are also suitable for the operation of various materials and particle sizes and can more easily adapt to upstream ‘abnormal’ process conditions

– Cocurrent is suitable for materials with higher moisture content and provides rapid evaporation without overheating the product. Countercurrent has the largest temperature gradient and helps reduce product moisture

– Reduce equipment size and associated capital and operating costs

– Promote diffusion drying

– Relatively low fan power and low headroom

– Save energy