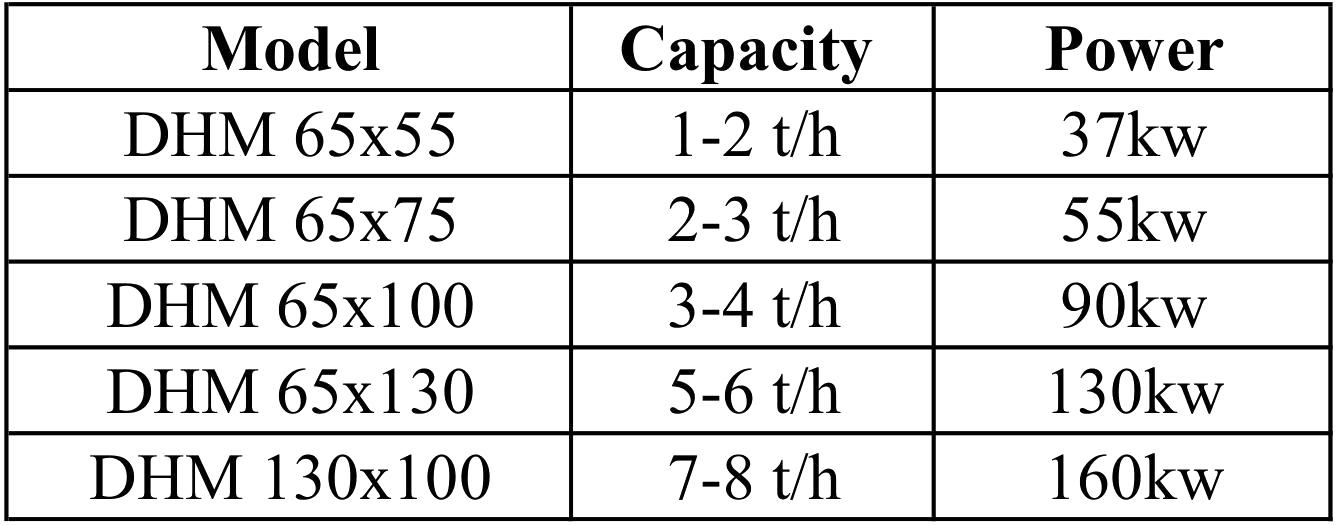

Hammer Mill DHM65x75

Wood Crusher Machine 2-3t/h

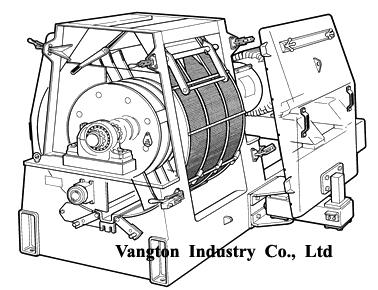

Hammer mill has very classic structure – hammers are fixed on the roller, when it rotating, the bigger material will be beaten and become smaller. There are hammer mill for plastic, for stone, for metal… The DHM series is specially designed for pellet making plant.

Working Principles:

The raw material is feed into the feeding hopper. Feeding hopper connected with the hammer chamber, the material falls down into the crusher from the top and it is beaten and crushed (hammered) by the blades, which rotating with a high speed rotating. By the help of centrifugal force and the continuous squeezing, the material crushed, and beaten by the hammer mill blades. The crushed materials which can go through the hoses on the screen, will be collected by the rotor centrifugal force and fan suction force (air force). While the chips, which are not mall enough to go through the holes, will continue the process, until get the suitable sizes. The crushed sawdust will be collected and discharged from the lower body of the crusher (hammer mill).