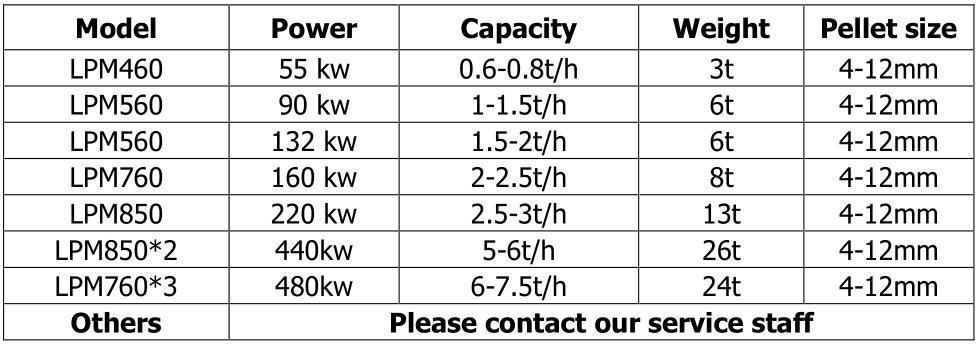

Wood Pellet Machine LPM460

0.8-1t/h Biomass Pellet Mill

Vertical Ring Die Biomass Wood Sawdust Pellet Mill (Pellet Machine) is a very stable and classic type of pellet machine. Can be used for small business and mass production.

Vertical Pellet Machine Gear Box Pellet Machine Horizontal Pellet Machine Flat Die Pellet Machine

The LPM pellet machine is widely used for biomass fuel making.

How to make pellet

1. Using Wood Chipper + Wood Crusher (Hammer Mill) to get powder from raw materials.

2. Using Dryer (rotary drum dryer / Air-flow dryer) to reduce the water consent. If the raw material is very dry (less than 8%), the dryer is not in need.

3. Feed sawdust (or other crushed and dried materials) into pellet machine. For big capacity will need crew feeder.

4. After granulation, the pellets’ temperature will be high. They mustn’t packing directly. At this time, a pellet cooler is needed.

After cooling pellets will go through a screen. The qualified pellets will be collected and go ahead, while not qualified and the powder will be removed.

5. Using pellet packing machine, putting pellets into bags.

Different structures of pellet machines

Advantages of ring die pellet machine over Flat Die Pellet Mill

1. They are large and big. Can be used for industrial production.

2. This type of pellet machine is designed for hard fiber.

3. The service life of ring die pellet machine is far more longer than flat die pellet mill.

4. Ring die pellet machine can produce pellets with high density, the surface is very smooth and beautiful to sell them as goods.