Wood Pellet Machine LPM760

2-2.5t/h Biomass Pellet Mill

Vertical Ring Die Biomass Wood Sawdust Pellet Mill is a very stable and classic type of pellet mill. Can be used for small business and mass production.

Vertical Pellet Machine Gear Box Pellet Machine Horizontal Pellet Machine Flat Die Pellet Machine

Advantages of biomass pellet machine

1. Vertical mold, vertical supply; no raw material arch, easy to dissipate heat.

2. The mold is fixed, the drum is rotated, the material is centrifuged and evenly distributed.

3. Double-layer mold, dual use for upper and lower, large capacity, energy saving.

A complete pellet machine line included the machines below:

1. Wood chipper machine – Usually a pellet machine line start with wood chipper machine, but some times will need a debarker before it. Debarker is a machine that remove tree bark, so the pellets will be very clean and low ash.

2. Wood crusher (grinding machine) – For making pellets, the material should be less than 10 mm (usually 3-5 mm, sometime require 1 mm) . If the raw material is straw, the first step will be crusher.

3. Drying machine (drum rotary dryer or air-flow dryer) – normally use drum rotary dryer, for very small capacity will use air-flow dryer to save cost.

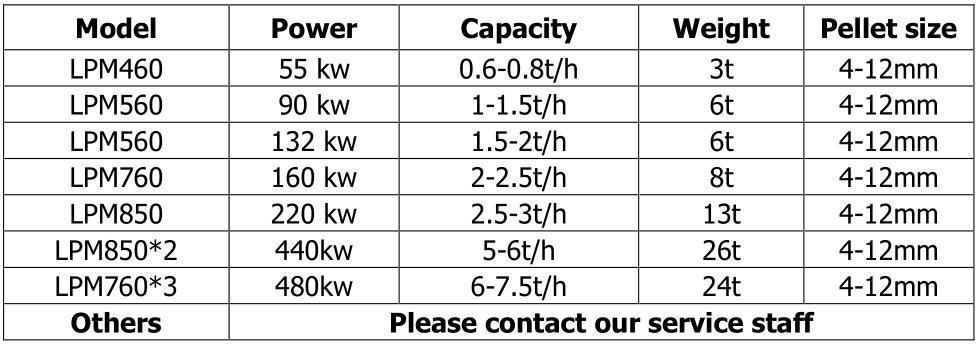

4. Pellet machine – pellet machine is the heart of the producing line. Our pellet machines are very classic, clients using for years, and give a high satisfaction. If you need suggestion on choosing the type of pellet machine, please contact with our sales staff.

5. Pellet Cooler – pellet cooling machine designed with a shaking screen. The pellets need to be cooled down to the room temperature, and also remove the unqualified pellets out.

6. Pellet packing machine. The packing machine have 2 types. Semi Automatic packing machine and fully automatic bagger. Client can choose depends on the budget.

7. Palletizer.

Vangton pellet machines

Energy-saving biomass wood pellet machine:

1. Our company is a manufacturer of pellet plant, producing complete machines for wood pellets production lines. The main products are pellet machines, hammer mills, wood crushers, wood chippers, drying coolers, and packaging machines.

2. This series of biomass wood chipper has low viscosity, such as wood chips, rice husk, coffee husk, crop straw, straw, peanut husk, sunflower seed, palm husk and other biomass waste. Suitable for thin materials such as paper and plastic, fertilizer materials such as animal waste and plant waste.

3. Biomass sawdust pellet making machine adopts the heart part and adopts “double-layer mold” as a unique structure. The roller is made of wear-resistant alloy, which greatly prolongs the service life of the part. For drive components, grease is automatically filtered and properly lubricated. Special design, reasonable structure, low power consumption and high efficiency

4. Biomass sawdust pellet making machine includes an automatic lubrication spare oil system, which can automatically lubricate spare oil. This technology, such as rollers, vertical shafts, gears and bearings, has been granted domestic patents.

5. On the other hand, make this series of biomass sawdust sawdust fans or machines with bag dust collectors work normally, and it is very environmentally friendly to clean the dust. On the other hand, the hot temperature of the spare parts inside the granulator can be cooled to ensure continuous operation for a long time. This letter is that our products are different from those of other suppliers.